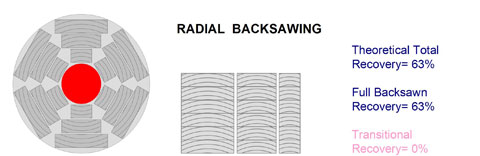

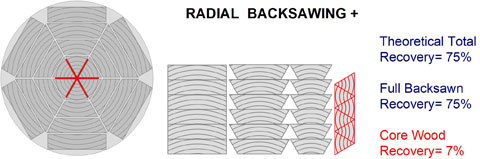

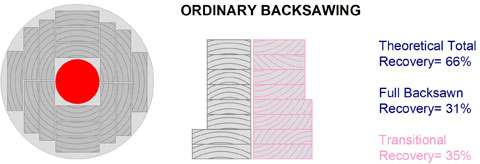

| A theoretical analysis of a 52 cm pruned or natural grown log with anticipated 15 cm defective core is made. No allowance is made for log taper. Chosen log size provides comparison results for maximum 20 cm board production for both systems. Standard 5 cm by 7.5, 10, 12.5, 15, 17.5 and 20 cm sizes are used to ascertain theoretical recovery and board quality related to growth ring orientation |  |